Regulations and society’s demands for product reliability have become increasingly strict in recent years. Amid calls for maintenance of high quality and safety, we are also developing non-pharmaceutical businesses including the diagnostics business and therapeutic applications.

While responding flexibly and quickly to changes in the business environment, we are providing a stable supply of high-quality products in compliance with relevant laws and regulations, aiming to earn greater trust and achieve the long-term vision “Vision 110.”

Changing environment(internal and external)

- Growing calls for pharmaceutical companies to ensure reliability

- Diversification and increasing complexity of drug discovery modalities

Opportunities

- Growing demand to supply high-quality products

- Establishment of quality and safety management systems in new Modalities

Risks

- Tighter regulations at home and abroad

- Quality issues in domestic and international supply chains

Medium-term business plan

Vision 110 –Stage1– initiatives

Business strategyStrengthening reliability assurance system to support comprehensive business development

- Strengthen our legal compliance system for pharmaceutical matters

- Promote prompt and reliable responses to changes in the environment surrounding reliability assurance

Reliability assurance system

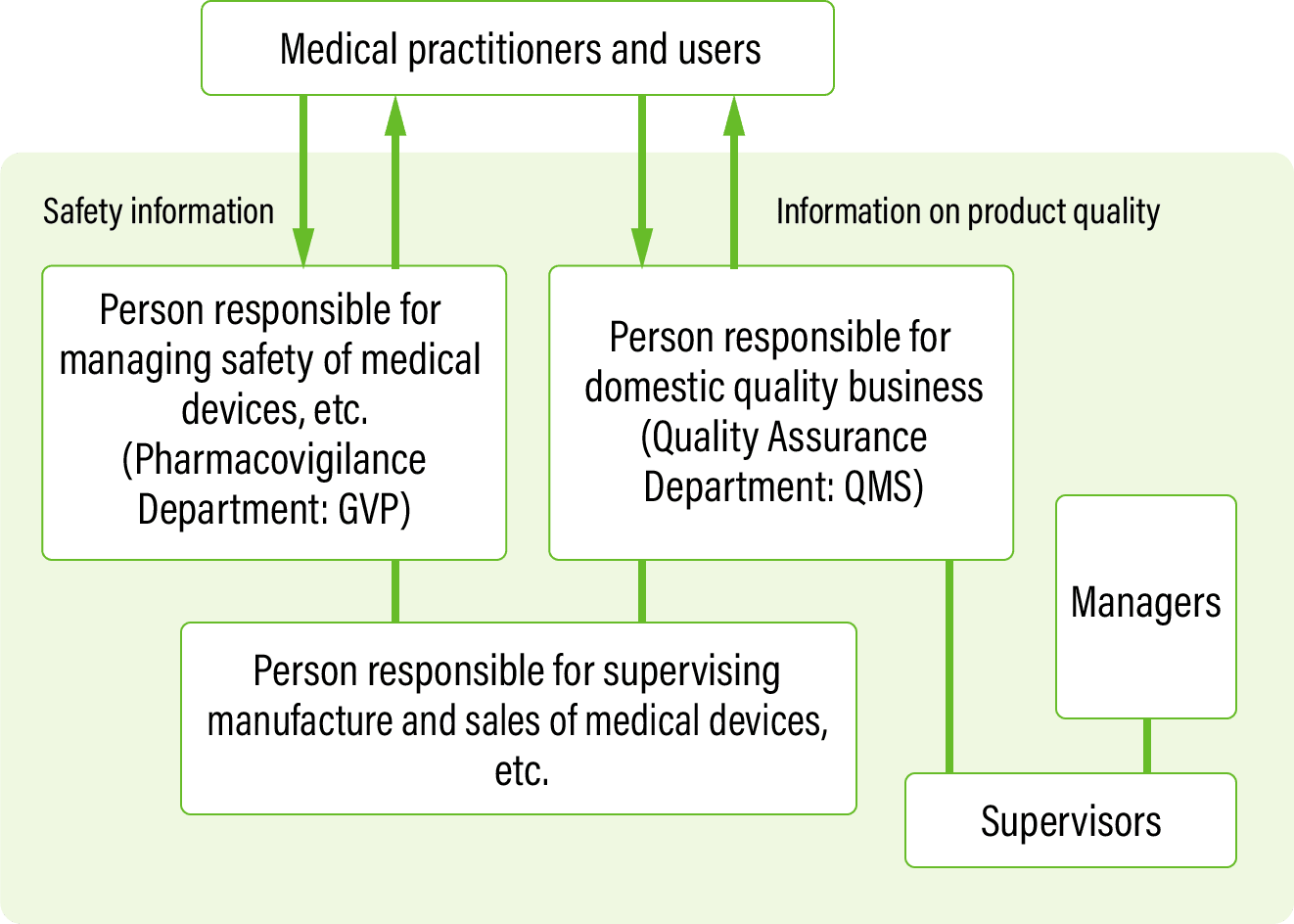

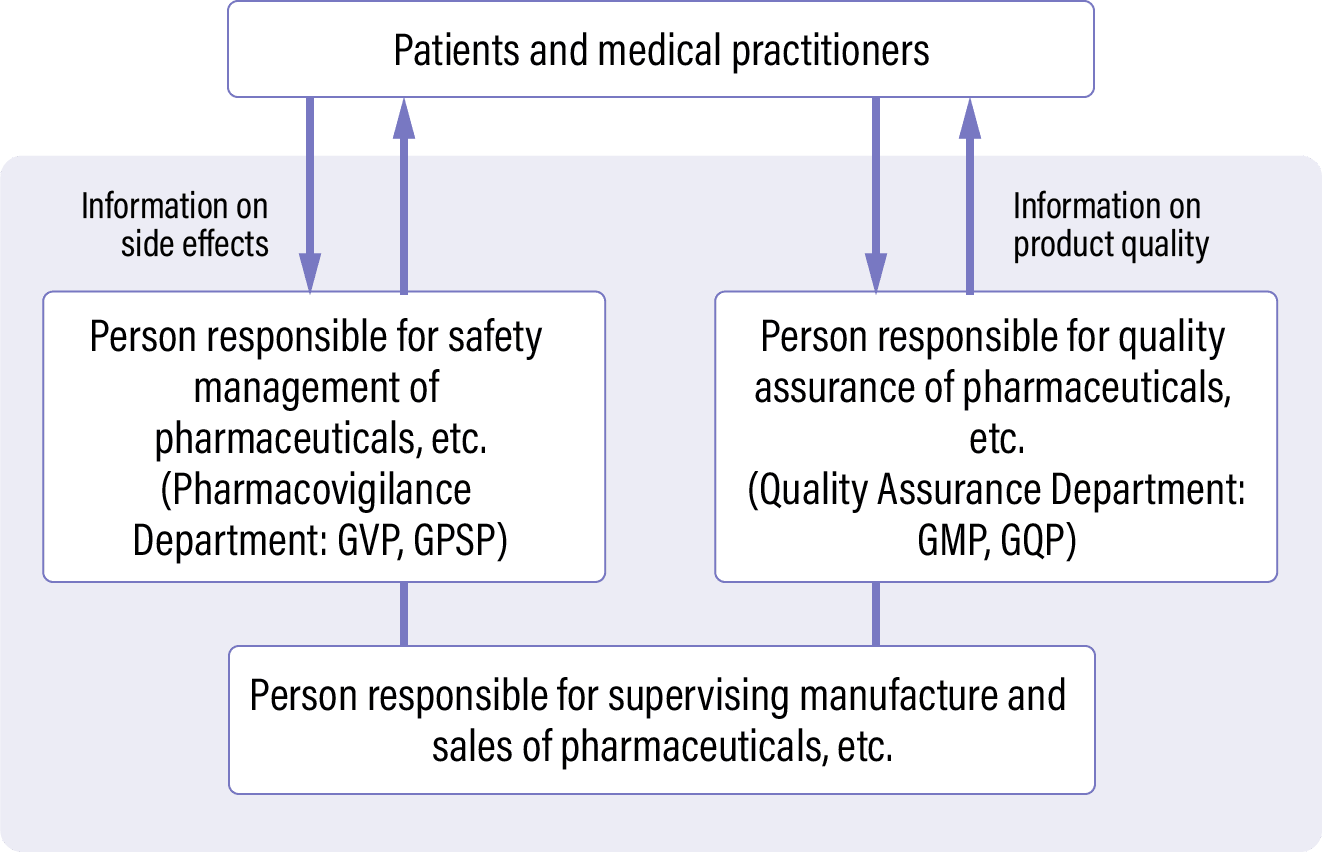

To ensure the stable supply of high-quality products, the roles and responsibilities of the accountable corporate officers and three senior managers involved in manufacturing and sales are clearly stipulated as per the Act on Securing Quality, Efficacy and Safety of Products Including Pharmaceuticals and Medical Devices. At the same time, the Group complies with the Good Quality Practice (GQP) and Good Vigilance Practice (GVP) standards for pharmaceuticals. In the diagnostics business, we have established a system that conforms to the Quality Management System (QMS) standard for manufacturing and managing medical devices, in vitro diagnostics, quality control, and GVP.

Our Quality Assurance & Reliability Division, which plays a central role in this process, coordinates with the R&D, manufacturing, and sales divisions to promote unified product reliability assurance initiatives aimed at providing products and information that patients and medical practitioners can use with confidence.

In addition, we promote proper use of our products and assure their reliability by faithfully and promptly responding to aftersales inquiries from patients and medical practitioners about products’ efficacy, safety, and quality.

Quality assurance

The Kyorin Group has a quality policy for both ensuring product quality and providing stable supplies. We are strengthening operation of our manufacturing centers through management of quality risk based on scientific evidence.

For pharmaceuticals, we have established a system to supply high-quality products based on GMP standards in cooperation with Group plants and other facilities from the development stage.

After launches, we carry out quality assurance in compliance with GQP standards. We have also created a distribution system that conforms to Good Distribution Practice (GDP) standards for pharmaceutical products, aiming to maintain product quality and ensure the integrity of distribution processes, as we strive to guarantee product quality and stable supplies from development and manufacturing to distribution.

For in vitro diagnostics and medical devices (diagnostics business), we are committed to providing high-quality products by practicing quality assurance in compliance with QMS standards across all stages, from design and development to sales.

Safety management

Drugs can be effective for treating patients (benefits) but can also have adverse side effects (risks). Therefore, during the development phase, we collect and manage safety information on investigational new drugs and appropriately monitor and evaluate changes in the safety profile of those drugs. After a product is launched, moreover, side effects unforeseen during the development phase may become apparent.

For this reason, it is important to collect and analyze a wide range of information about benefits and risks after a product is launched and to quickly provide appropriate information to the medical community, with the balance taken into account.

The Kyorin Group formulates risk management plans and collects and manages safety information by individual product. This approach includes drug-monitoring activities for pharmaceuticals and medical devices in compliance with GVP standards to ensure their safety and proper use. We also conduct post-launch investigations in accordance with Good Post Marketing Study Practice (GPSP) standards to collect and evaluate information about the safety and efficacy of pharmaceuticals after they are launched.

Quality Policy

KYORIN Pharmaceutical’s Quality Policy

“Kyorin continues to fulfill its mission of cherishing life and benefiting society by contributing to better health.” Following this corporate philosophy, we provide high-quality products that are trusted by patients and medical practitioners.

- We engage in appropriate quality-related activities in compliance with relevant laws, regulatory requirements, and internal standards.

- We practice quality risk management based on scientific knowledge to ensure product reliability.

- We strive to raise employee awareness of quality and foster a quality-driven culture with ongoing education.

- We work closely with subcontracted manufacturers and suppliers to ensure stable supplies of high-quality products.

- We listen and respond sincerely to patients, medical practitioners, and others and actively strive to improve product quality.

Manufacturing and Sales Structure

Pharmaceuticals

In vitro diagnostics/medical devices